Air conditioners are a must in the harsh climate of GCC both in office, mall home and labour accomodation. Quality accomodation is essential for your team to stay in good health and perform at their full potential. However air conditioners, especially when badly managed consume a lot of power, the end result is very expensive energy bills.

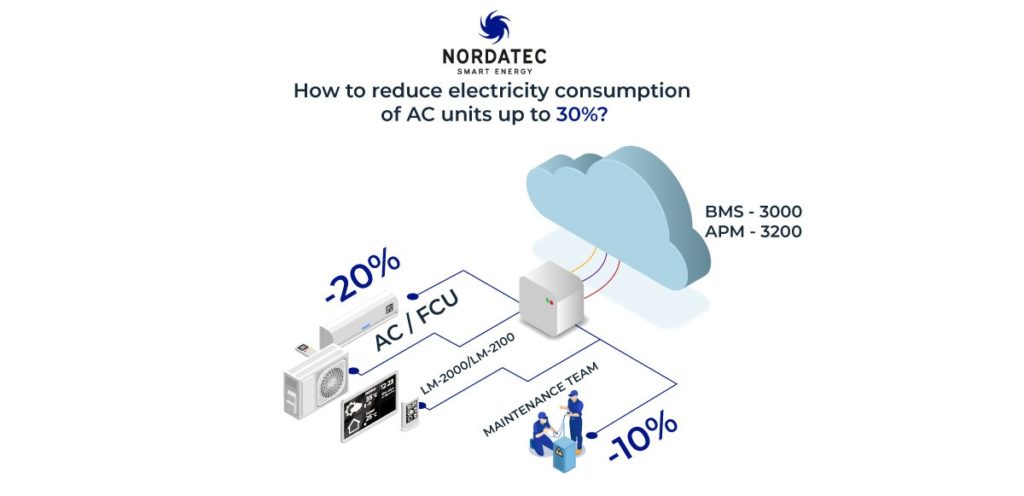

In this article we will be sharing how the energy saving journey will yield the 30% savings. The savings fall into 3 parts:

- Thermal energy saved with time and temperature management

- Energy saved with active monitoring and focused actions

- Operational and organizational savings

1- Energy Efficiency with active management of temperature and timing (BMS-3000)

In labour camp, the temperatures are often uncontrolled. Despite clear indications from Dubai municipality that state a temperature in the rooms to be between 22.5 and 25 degree C, the actual temperatures are to let in the hand of the end-user. Observed setpoint temperatures can be as low as 16 degrees. Such cold settings are very costly for the organisation.

In an area cooled with split units, driving the AC unit to extreme settings results in the compressor running continuously without respecting its natural cycling pattern. The continuous running is detrimental to efficiency and results in an increase in cooling costs by 15%-20% without benefits on cooling.

The solution: Once the initial temperature setpoint is raised just enough to avoid overcooling, the energy consumption will drop accordingly by 15%-20%. Each degree then further reduces the consumption by 9%. This means that raising the setpoint with just 1.5 degree will immediately deliver at least 20-25% electricity savings.

In areas with district cooling, there is no limit on the cooling energy delivered by the cooling plant. Overcooling to 19 deg leads to expensive cooling overconsumption. Each additional C-degree in setpoint reduces the consumption with about 9%. This means that a mere 2.2 degree increase already delivers an immediate 20% savings in district cooling.

Such minimal setpoint increase will have no impact on the comfort, A setpoint temperature of 22 instead of 19 remains very acceptable. Let us remind that most users who pays their cooling bills set the temperature setpoint at 24 degrees.

Finally managing the operations timing of the cooling can have a significant impact on energy consumption . Timing management contributes to raising the average temperature of the camp and is relatively easy to implement since labour schedule is also well known.

The active management of the temperature and timing delivers at least 20% reduction of direct energy consumption.

2 – Monitoring Energy Use and focused action (APM-3200)

Understanding your energy use patterns is a very important first step in controlling and reducing your energy use. Our BMS-3000 software is a light building management system pilots units equipped with compatible LM-2000 and LM-2100 unit managers record the energy use in real time and graphs and help identify the major consumers or inefficient units.

Based on previous studies, we know that 90% of the AC fleet is working in poor conditions. These units consume 10%-50% more energy than needed. The figures above are based on a series of surveys including planned inspections of 156 AC-units. The units part of the survey were all serviced and owner believes they are in good condition.

This is the beginning of an action plan to restore efficiency in the poorest unit. Once the poorest and most consuming units are known, an action can be started to restore efficiency in the poorest units.With focused maintenance, the maintenance team is able to delay unneeded maintenance and instead focus on the units that really need it before the cost of malfunction accumulates.

Action includes low-cost or no cost action such as cleaning of outdoor units or filters but it could also be action such as ensuring correct charge, repair faulty expansion valve, contactor or capacitor. Such focused low-cost maintenance will ensuring Ac units work in good conditions. The results are immediately visible in the consumption figures and ensure that results are visible to the whole team.

Looking at above figures, constant AC-by-AC monitoring and focused action thus ensures a typical saving of 10%.

3 – Operational savings and team work

The IOT system includes several important components to deliver operational savings:

- Remote configuration : camp boss / facility manager does not need to come to site for setting configuration of temp and running time of the Ac.

Compared to the current generally used method of manually switching on and off multiple AC twice a day, savings in a 200 room building is typically 0.4 full time job. In Dubai current costs, it is roughly 1-2% of the energy consumption in the building. - Sharing of issues and results across the team: the APM-3200 with detailed room-by-room reports on consumption, time and temperature, is a better communication tool across the organization than manual observation. This ensures that the team knows the matters and shares an action plan accordingly.

- Protection against Covid exposure: the team needs to be physically less in the camp, and this further contributes to a safer environment, especially during Covid exposure risks.